Arduino print serial text (Ladder Diagram) exapmple

Still trying to get familiar with PLC programming (using OpenPLC), I started with some examples:

Ladder Diagram on OpenPLC (Arduino Uno as the device)

Some introductions about basic syntax and examples are on wikipedia, and here's an example project in OpenPLC editor, which is outputting a line of text through the serial port at the same frequence of LED blink.t

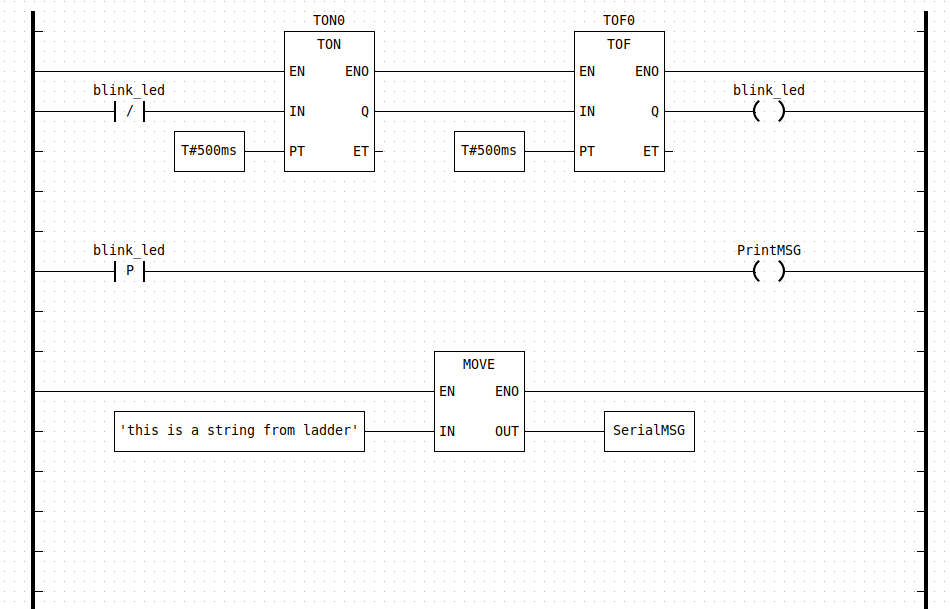

This is how the LD program looks like:

Blink LD program

There are mainly 3 parts.

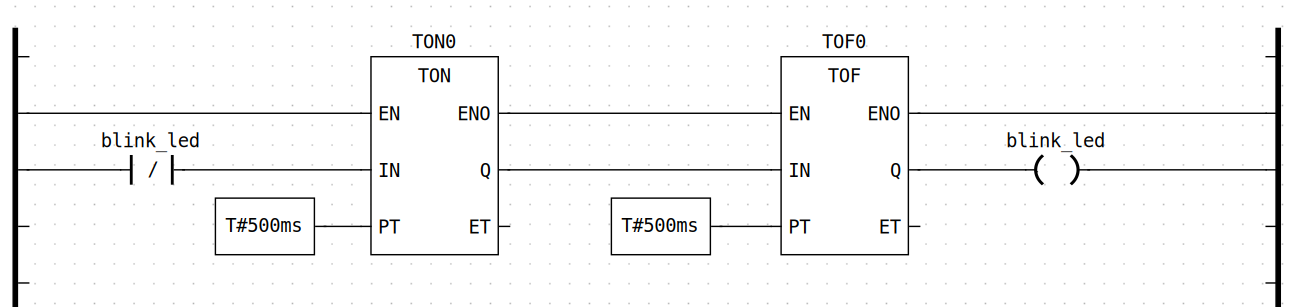

Part 1: timer + relay

This part defines the interval / frequency of LED blink. On the left there is an rung input ( or "checkercontact" in ladder diagrams) —[ ]— , it's taking the on-board LED's status as an input. TON0 and TOF0 are timer relays, what they do is to generate a high of low voltage output at the Q end according to the preset time duration.

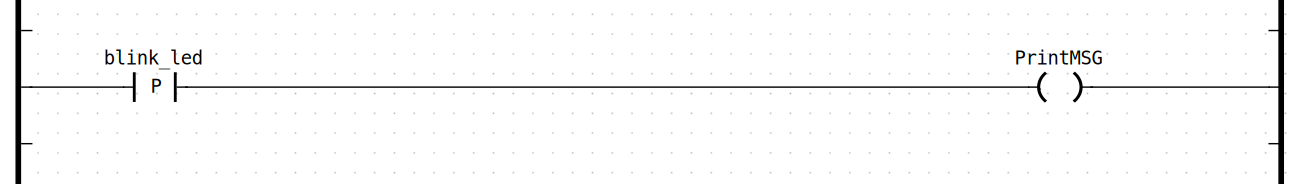

rising edge enable PrintMSG

This part is using the rising edge of the LED pin to enable the PrintMSG function,

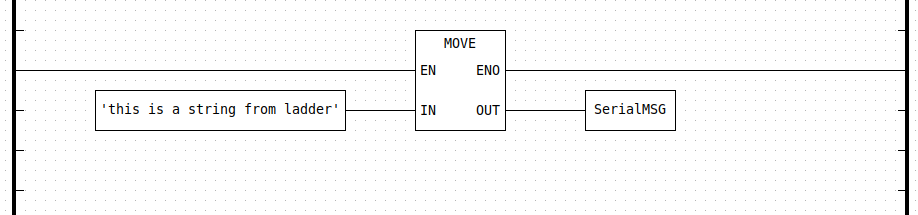

Providing string literal to the PrintMSG function

And eventually the message printing process is an arithmetic operation called MOVE , what it does is to copy the string literal from in pin to an external variable called SerialMSG on the OUT pin.

It still looks a bit confusing at this point, but there's also the Arduino side of the program: ```c //////////////////////////////// sketch section ////////////////////////////////

// This is the Arduino side of the project. The functions sketch_setup() and // sketch_loop() provide the same functionality of the setup() and loop() // functions of a regular Arduino sketch. On top of this code editor there is a // variable table. You can add variables there that are shared between the // arduino code and the PLC code. Since they are shared, you can, for example, // read a sensor on the arduino sketch and use the reading in a PLC program. // On the PLC side you must declare the same variable with the class "external" // before being able to use it in your program.

// This Arduino sketch implementation is compatible with virtually every library // or code you can possibly run on the regular Arduino IDE. You can create your // own functions and also #include external libraries (as long as they are also // installed on your Arduino IDE). The only catch is that your sketch_loop() // function cannot block (long while loop or delays), or else your PLC code will // block as well.

// Notes about this particular demo: Since this demo uses the serial port, you // cannot enable Modbus Serial on your project, otherwise it will conflict with // the messages being printed from this sketch. Also, this sketch shares a // STRING with the PLC side. This is not a regular c-string, it is an IEC 61131 // STRING. Variables shared between the PLC and Arduino sketch are always IEC // 61131 variables. For normal datatypes like INT, REAL, DINT, etc, there are // direct equivalents in C (int16_t, float and int32_t respectively), so you // shouldn't have any problems with those. An IEC STRING however is a more // complex structure. You can typecast an IEC STRING into a c-string by using // (char *)STRING.body as shown in the example below.

void sketch_setup() { Serial.begin(115200); Serial.println("Hello World! I'm starting now..."); }

void sketch_loop() { if (PrintMSG) { Serial.println((char *)SerialMSG.body); } } ```

In this case, it's using the variables ( PrintMSG and SerialMSG ) modified in the ladder diagram in the sketch_loop function.

The output files of OpenPLC compiling process

When the program is being build, there would be some .obj and lib files generated:

Start build in /home/ray/Downloads/OpenPLC Editor for Linux/OpenPLC_Editor/editor/examples/Arduino_Serial_Print/build

Generating SoftPLC IEC-61131 ST/IL/SFC code...

Collecting data types

Collecting POUs

Generate POU ArduinoPrint

Generate Config(s)

Compiling IEC Program into C code...

Extracting Located Variables...

C code generated successfully.

PLC :

[CC] plc_main.c -> plc_main.o

[CC] plc_debugger.c -> plc_debugger.o

PLC :

[CC] Config0.c -> Config0.o

[CC] Res0.c -> Res0.o

0 :

[CC] CFile_0.c -> CFile_0.o

Linking :

[CC] plc_main.o plc_debugger.o Config0.o Res0.o CFile_0.o -> Arduino_Serial_Print.so

Successfully built.

Build MD5: 4e8dd5085880b489b8a48c8bf30f9588And actually the Arduino code in the previous section is in CFile_0.c:

/* Code generated by Beremiz c_ext confnode */

#ifdef ARDUINO_PLATFORM

#include <stdio.h>

#include "iec_types_all.h"

/* User variables reference */

extern "C" __IEC_STRING_t CONFIG0__SERIALMSG;

#define SerialMSG CONFIG0__SERIALMSG.value

extern "C" __IEC_BOOL_t CONFIG0__PRINTMSG;

#define PrintMSG CONFIG0__PRINTMSG.value

/* User sketch */

// This is the Arduino side of the project. The functions sketch_setup() and

// sketch_loop() provide the same functionality of the setup() and loop()

// functions of a regular Arduino sketch. On top of this code editor there is a

// variable table. You can add variables there that are shared between the

// arduino code and the PLC code. Since they are shared, you can, for example,

// read a sensor on the arduino sketch and use the reading in a PLC program.

// On the PLC side you must declare the same variable with the class "external"

// before being able to use it in your program.

// This Arduino sketch implementation is compatible with virtually every library

// or code you can possibly run on the regular Arduino IDE. You can create your

// own functions and also #include external libraries (as long as they are also

// installed on your Arduino IDE). The only catch is that your sketch_loop()

// function cannot block (long while loop or delays), or else your PLC code will

// block as well.

// Notes about this particular demo: Since this demo uses the serial port, you

// cannot enable Modbus Serial on your project, otherwise it will conflict with

// the messages being printed from this sketch. Also, this sketch shares a

// STRING with the PLC side. This is not a regular c-string, it is an IEC 61131

// STRING. Variables shared between the PLC and Arduino sketch are always IEC

// 61131 variables. For normal datatypes like INT, REAL, DINT, etc, there are

// direct equivalents in C (int16_t, float and int32_t respectively), so you

// shouldn't have any problems with those. An IEC STRING however is a more

// complex structure. You can typecast an IEC STRING into a c-string by using

// (char *)STRING.body as shown in the example below.

void sketch_setup()

{

Serial.begin(115200);

Serial.println("Hello World! I'm starting now...");

}

void sketch_loop()

{

if (PrintMSG)

{

Serial.println((char *)SerialMSG.body);

}

}

#endifAnd the Ladder Diagram was translated into C files first, it's in a file called POUS.c:

void LOGGER_init__(LOGGER *data__, BOOL retain) {

__INIT_VAR(data__->EN,__BOOL_LITERAL(TRUE),retain)

__INIT_VAR(data__->ENO,__BOOL_LITERAL(TRUE),retain)

__INIT_VAR(data__->TRIG,__BOOL_LITERAL(FALSE),retain)

__INIT_VAR(data__->MSG,__STRING_LITERAL(0,""),retain)

__INIT_VAR(data__->LEVEL,LOGLEVEL__INFO,retain)

__INIT_VAR(data__->TRIG0,__BOOL_LITERAL(FALSE),retain)

}

// Code part

void LOGGER_body__(LOGGER *data__) {

// Control execution

if (!__GET_VAR(data__->EN)) {

__SET_VAR(data__->,ENO,,__BOOL_LITERAL(FALSE));

return;

}

else {

__SET_VAR(data__->,ENO,,__BOOL_LITERAL(TRUE));

}

// Initialise TEMP variables

if ((__GET_VAR(data__->TRIG,) && !(__GET_VAR(data__->TRIG0,)))) {

#define GetFbVar(var,...) __GET_VAR(data__->var,__VA_ARGS__)

#define SetFbVar(var,val,...) __SET_VAR(data__->,var,__VA_ARGS__,val)

LogMessage(GetFbVar(LEVEL),(char*)GetFbVar(MSG, .body),GetFbVar(MSG, .len));

#undef GetFbVar

#undef SetFbVar

;

};

__SET_VAR(data__->,TRIG0,,__GET_VAR(data__->TRIG,));

goto __end;

__end:

return;

} // LOGGER_body__()

static inline STRING __ARDUINOPRINT_MOVE__STRING__STRING1(BOOL EN,

STRING IN,

ARDUINOPRINT *data__)

{

STRING __res;

BOOL __TMP_ENO = __GET_VAR(data__->_TMP_MOVE14_ENO,);

__res = MOVE__STRING__STRING(EN,

&__TMP_ENO,

IN);

__SET_VAR(,data__->_TMP_MOVE14_ENO,,__TMP_ENO);

return __res;

}

void ARDUINOPRINT_init__(ARDUINOPRINT *data__, BOOL retain) {

__INIT_LOCATED(BOOL,__QX0_3,data__->BLINK_LED,retain)

__INIT_LOCATED_VALUE(data__->BLINK_LED,__BOOL_LITERAL(FALSE))

TON_init__(&data__->TON0,retain);

TOF_init__(&data__->TOF0,retain);

__INIT_EXTERNAL(STRING,SERIALMSG,data__->SERIALMSG,retain)

__INIT_EXTERNAL(BOOL,PRINTMSG,data__->PRINTMSG,retain)

R_TRIG_init__(&data__->R_TRIG1,retain);

__INIT_VAR(data__->_TMP_MOVE14_ENO,__BOOL_LITERAL(FALSE),retain)

__INIT_VAR(data__->_TMP_MOVE14_OUT,__STRING_LITERAL(0,""),retain)

}

// Code part

void ARDUINOPRINT_body__(ARDUINOPRINT *data__) {

// Initialise TEMP variables

__SET_VAR(data__->TON0.,EN,,__BOOL_LITERAL(TRUE));

__SET_VAR(data__->TON0.,IN,,!(__GET_LOCATED(data__->BLINK_LED,)));

__SET_VAR(data__->TON0.,PT,,__time_to_timespec(1, 500, 0, 0, 0, 0));

TON_body__(&data__->TON0);

__SET_VAR(data__->TOF0.,EN,,__GET_VAR(data__->TON0.ENO,));

__SET_VAR(data__->TOF0.,IN,,__GET_VAR(data__->TON0.Q,));

__SET_VAR(data__->TOF0.,PT,,__time_to_timespec(1, 500, 0, 0, 0, 0));

TOF_body__(&data__->TOF0);

__SET_LOCATED(data__->,BLINK_LED,,__GET_VAR(data__->TOF0.Q,));

__SET_VAR(data__->R_TRIG1.,CLK,,__GET_LOCATED(data__->BLINK_LED,));

R_TRIG_body__(&data__->R_TRIG1);

__SET_EXTERNAL(data__->,PRINTMSG,,__GET_VAR(data__->R_TRIG1.Q,));

__SET_VAR(data__->,_TMP_MOVE14_OUT,,__ARDUINOPRINT_MOVE__STRING__STRING1(

(BOOL)__BOOL_LITERAL(TRUE),

(STRING)__STRING_LITERAL(28,"this is a string from ladder"),

data__));

if (__GET_VAR(data__->_TMP_MOVE14_ENO,)) {

__SET_EXTERNAL(data__->,SERIALMSG,,__GET_VAR(data__->_TMP_MOVE14_OUT,));

};

goto __end;

__end:

return;

} // ARDUINOPRINT_body__()The ARDUINOPRINT_body__() contains the corresponding ladder diagram operations.

Problems

Is the compiled .so library files able to be executed on actual devices? Is it executed well in local simulator / development runtime environment?

How exactly is the compilation process executed? Is it possible to expose some internal variables or input to external entities? To what degree is the whole program configurable?

What are the possible limits for PLC programs ( if the developers want to create FMUs for these programs )? For example if some variables are supposed to be accessable by external entities rather than being private withing the FMU, would there be a guideline / to-do / not-to-do list for for the PLC programs?

Next Steps

- Try to run the example project on simulator, just to make sure it works.

- Check about different examples, including different languages in IEC 61131-3 and examples that are supposed to run on other PLC devices, pay attention to whether or not there are differences in generated C code.